The Impact of Data on Reducing Construction Waste and Downtime

Discover how data-driven strategies can cut costs, improve efficiency, and enhance project outcomes in construction. Reduce waste, minimize downtime, and boost profitability by integrating data into your processes.

Check out even more resources

How Digital Work Orders Impact Your Key Business Outcomes

Is your company still using paper sheets to manage work orders? The drawbacks of using paper forms are often hidden, making it difficult to understand the true impact of paper forms on a business…

See How Centurion Got Amazing ROI from GoCanvas

Centurion is the largest heavy haulage provider in Australia. They deliver national supply chain solutions to the resources, energy, construction & retail sectors throughout Western Australia, Queensland & the Northern Territory…

5 Tips to Improve How Your Business Collects Data

Companies rely on collecting data in order to operate. In a fast-changing world, companies that focus on streamlining and improving their data collection processes will be able to do more. The good news is that it’s become easier than ever for businesses of all…

Connect with an Expert Today.

We’ll help you put together the right solution for your needs.

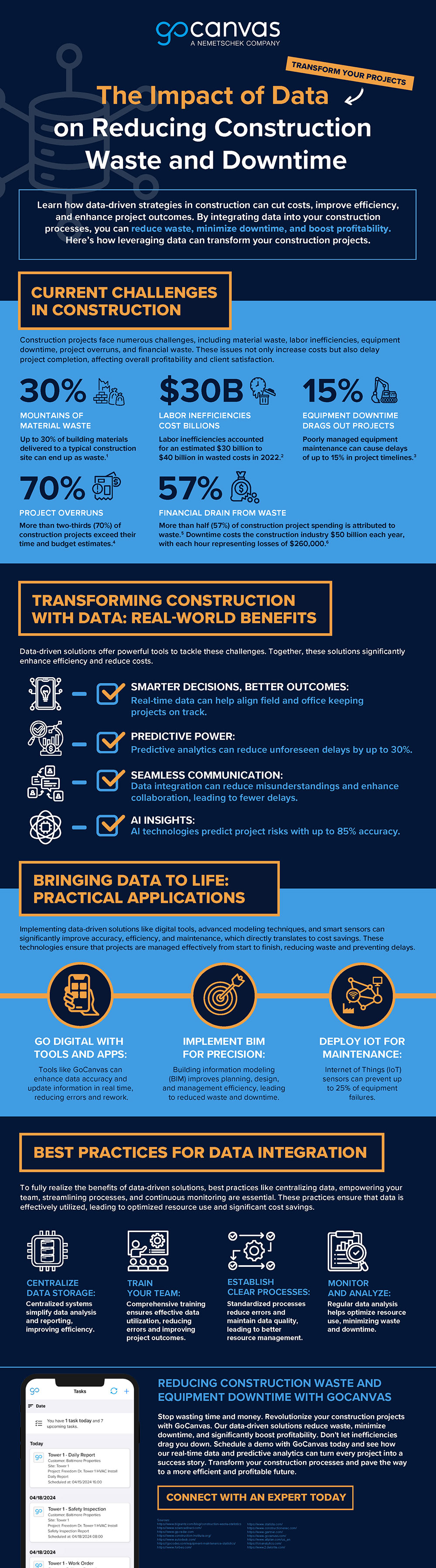

The Impact of Data on Reducing Construction Waste and Downtime

Learn how data-driven strategies in construction can cut costs, improve efficiency, and enhance project outcomes. By integrating data into your construction processes, you can reduce waste, minimize downtime, and boost profitability. Here’s how leveraging data can transform your construction projects.

Current Challenges in Construction

Construction projects face numerous challenges, including material waste, labor inefficiencies, equipment downtime, project overruns, and financial waste. These issues not only increase costs but also delay project completion, affecting overall profitability and client satisfaction.

- Mountains of material waste: Up to 30% of building materials delivered to a typical construction site can end up as waste. (ScienceDirect)

- Labor inefficiencies cost billions: Labor inefficiencies accounted for an estimated $30 billion to $40 billion in wasted costs in 2022. (GPRS)

- Equipment downtime drags out projects: Poorly managed equipment maintenance can cause delays of up to 15% in project timelines. (Construction Industry Institute)

- Project overruns: More than two-thirds (70%) of construction projects exceed their time and budget estimates. (Autodesk)

- Financial drain from waste:

Transforming Construction with Data: Real-World Benefits

Data-driven solutions offer powerful tools to tackle these challenges. Together, these solutions significantly enhance efficiency and reduce costs.

- Smarter decisions, better outcomes: Real-time data can help manage potential delays and keep projects on track. (Forbes)

- Predictive power: Predictive analytics can reduce unforeseen delays by up to 30%. (Statista)

- Seamless communication: Data integration can reduce misunderstandings and enhance collaboration, leading to fewer delays. (Construction Executive)

- AI insights: AI technologies predict project risks with up to 85% accuracy. (Gartner)

Bringing Data to Life: Practical Applications

Implementing data-driven solutions like digital tools, advanced modeling techniques, and smart sensors can significantly improve accuracy, efficiency, and maintenance, which directly translates to cost savings. These technologies ensure that projects are managed effectively from start to finish, reducing waste and preventing delays.

- Go digital with tools and apps: Tools like GoCanvas can enhance data accuracy and update information in real time, reducing errors and rework. (GoCanvas)

- Implement BIM for precision: Building information modeling (BIM) improves planning, design, and management efficiency, leading to reduced waste and downtime. (ALLPLAN)

- Deploy IoT for maintenance: Internet of Things (IoT) sensors can prevent up to 25% of equipment failures. (IoT Analytics)

Best Practices for Data Integration

To fully realize the benefits of data-driven solutions, best practices like centralizing data, empowering your team, streamlining processes, and continuous monitoring are essential. These practices ensure that data is effectively utilized, leading to optimized resource use and significant cost savings.

- Centralize data storage: Centralized systems simplify data analysis and reporting, improving efficiency. (Forbes)

- Train your team: Comprehensive training ensures effective data utilization, reducing errors and improving project outcomes. (Deloitte)

- Establish clear processes: Standardized processes reduce errors and maintain data quality, leading to better resource management. (Construction Executive)

- Monitor and analyze: Regular data analysis helps optimize resource use, minimizing waste and downtime. (Construction Industry Institute)

Reducing Construction Waste and Equipment Downtime with GoCanvas

Stop wasting time and money. Revolutionize your construction projects with GoCanvas. Our data-driven solutions reduce waste, minimize downtime, and significantly boost profitability. Don’t let inefficiencies drag you down. Schedule a demo with GoCanvas today and see how our real-time data and predictive analytics can turn every project into a success story. Transform your construction processes and pave the way to a more efficient and profitable future.

Sources:

BigRentz Construction Waste Statistics